Advantages of Titanium Material Processing for Precision Parts

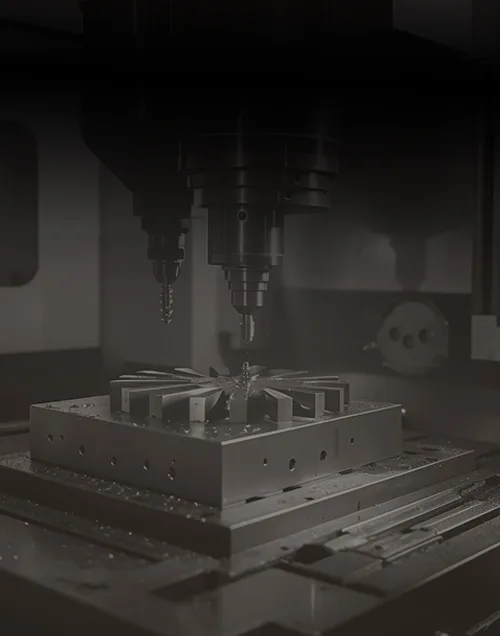

Despite the challenges in machining titanium, there are numerous benefits to processing it in various applications. With our professional technical knowledge and industry experience, we manufacture high-quality, precision titanium components for various industries. Some of the main advantages of using CNC machining of titanium materials to produce parts include:

- It has the highest strength-to-density ratio among all elements in the periodic table.

- It has natural rust and corrosion resistance.

- It is biocompatible.

- It is extremely durable and ductile.

CNC Machining of Titanium Materials Meets the Component Requirements of Various Industries

Due to the satisfactory properties of processed titanium and its alloys, the demand for them is steadily increasing. Although titanium parts are used in various industries, the specific application fields that typically require precision titanium components include:

- Medical equipment

- Surgical tools and implants

- Dental implants

- Aerospace components

- Defense applications

- Automotive parts

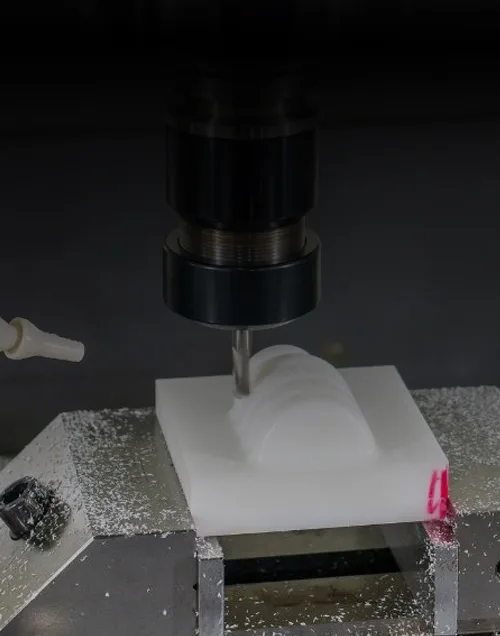

Titanium Material Processing for Medical Components

The material properties of titanium make it an excellent choice for applications related to implantable medical components and surgical instruments. Titanium is a biocompatible metal with corrosion resistance, strength, and durability. It can be cut into small sizes while still maintaining strength and structural integrity. Kansd provides precision CNC machining services for titanium materials to manufacture customized titanium medical components, such as:

- Conical, straight, or self-tapping bone screws

- Dental implant screws

- Forceps, cutters, and tweezers

- Dilators and tunneling devices

- Neurosurgical components

- Endoscopic equipment

- Aspiration needles, phacoemulsification needles, and ultrasonic needles

- Fixation plates

- And more

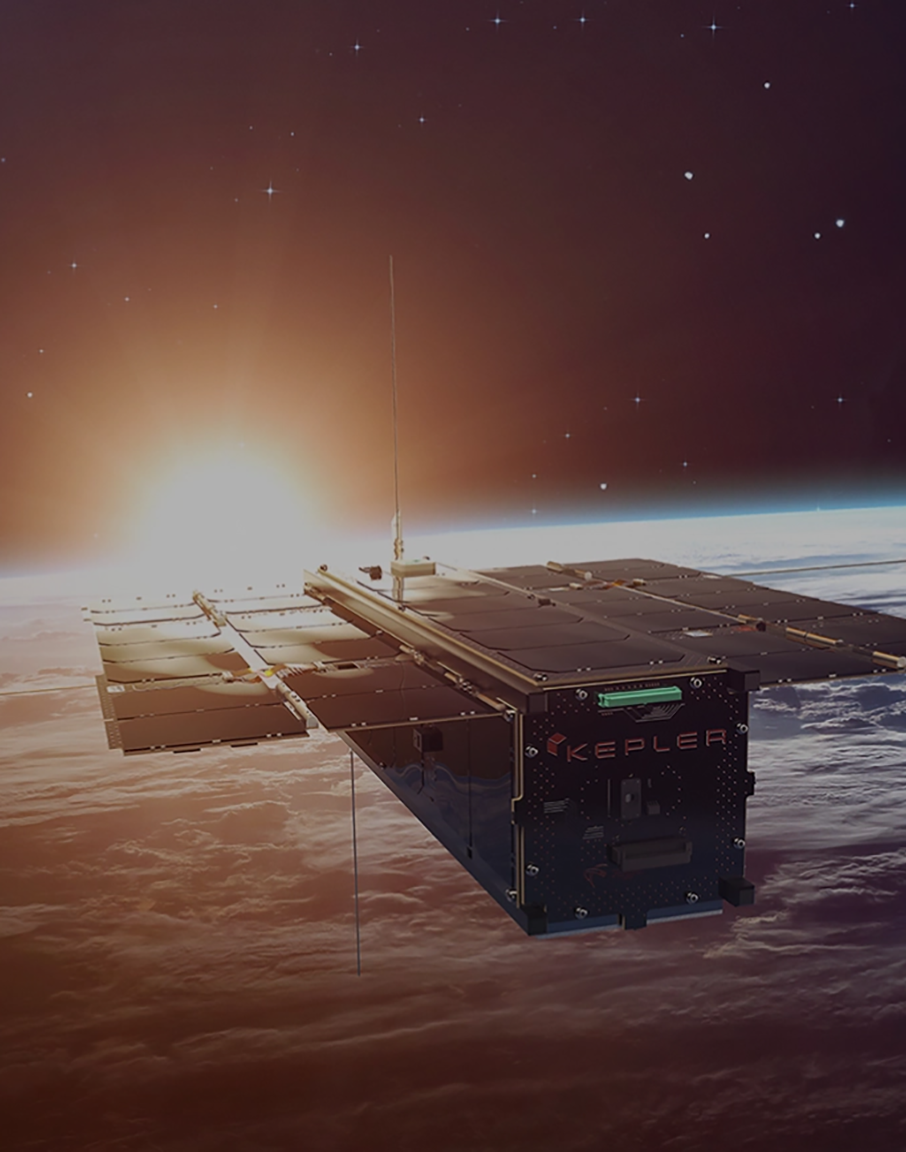

CNC Machining of Titanium Materials for Aerospace Components

The material properties of titanium have made it increasingly popular in the field of aerospace components. In aerospace components, weight and strength are crucial. Titanium has a high strength-to-density ratio and is very suitable for critical mission components. It also has fatigue strength, fracture durability, and crack resistance, which are highly favored in aircraft, shuttles, spacecraft, and other aerospace applications. The processing of titanium in the aerospace field can produce a variety of components, including:

- Fuselage materials

- Engine components

- Turbofan and compressor parts

We are well aware that in the aerospace industry, there are extremely high requirements for extreme precision, accuracy, and full compliance with standards, as even minor defects can lead to disastrous consequences. As your titanium material processing partner, we can produce CNC-machined titanium parts that meet most aerospace specifications, requirements, or regulations. Communicate with our technical engineers to learn what we can do for your titanium material processing project.

Kansd's Custom Precision Titanium Material Processing and CNC Services

Kansd is a company certified to ISO 13485:2016. Our quality standards meet or exceed the ANSI/ASQ z 1.4 standard, and we have the ability to meet military standards and specifications. We are proud to be your full-service partner, providing a full range of manufacturing services from conceptual design to production and delivery. In addition to titanium material processing, we also machine many unique and difficult-to-machine materials, including stainless steel processing, composite material processing, etc.

Machining Precision Parts with CNC Machining of Titanium Materials

Kansd has over 15 years of industry experience and uses CNC machining technology for titanium materials to achieve extremely high precision for parts in medical equipment, as well as in the aerospace and defense industries. Our high-quality CNC machining services are applicable to a variety of unique materials to meet your industrial application requirements in different industries.

CapabilitiesPrototypes and production partsMechanical ManufacturingMechanical Manufacturing Capability: Excellent Craftsmanship, Creating Exceptional QualityParts Manufacturing and ProcessingParts Manufacturing and Processing: Meticulous Craftsmanship, Creating Premium PartsMaterial Surface FinishesMaterial Surface Finishes: Refining Processes, Reinventing Material ExcellenceInspection and Quality ControlInspection and Quality Control: Precise Control, Quality AssuranceHeat Treatment ServicesHeat Treatment Services: Precise Temperature Control, Reinventing Material ExcellencePrecision AssemblyPrecision Assembly: Meticulous Craftsmanship, Achieving Perfect Combinations

CapabilitiesPrototypes and production partsMechanical ManufacturingMechanical Manufacturing Capability: Excellent Craftsmanship, Creating Exceptional QualityParts Manufacturing and ProcessingParts Manufacturing and Processing: Meticulous Craftsmanship, Creating Premium PartsMaterial Surface FinishesMaterial Surface Finishes: Refining Processes, Reinventing Material ExcellenceInspection and Quality ControlInspection and Quality Control: Precise Control, Quality AssuranceHeat Treatment ServicesHeat Treatment Services: Precise Temperature Control, Reinventing Material ExcellencePrecision AssemblyPrecision Assembly: Meticulous Craftsmanship, Achieving Perfect Combinations IndustriesDeveloping revolutionary productsAutomotivePrecision Machining Services for Auto Parts in the Automotive Manufacturing IndustryMedical Equipment & HealthcarePrecision Medical Machining ServicesMilitary and AerospacePrecision Machining Services for Military and Aerospace ManufacturingElectronics and SemiconductorPrecision Machining Services for Electronics and Semiconductor ManufacturingEnergy and Industrial EquipmentPrecision Machining Services for Energy and Industrial Equipment Manufacturing

IndustriesDeveloping revolutionary productsAutomotivePrecision Machining Services for Auto Parts in the Automotive Manufacturing IndustryMedical Equipment & HealthcarePrecision Medical Machining ServicesMilitary and AerospacePrecision Machining Services for Military and Aerospace ManufacturingElectronics and SemiconductorPrecision Machining Services for Electronics and Semiconductor ManufacturingEnergy and Industrial EquipmentPrecision Machining Services for Energy and Industrial Equipment Manufacturing Metal MachiningProtoypes and production partsTitanium Alloy MachiningPrecision CNC Machining of Titanium MaterialsCopper and Aluminum MachiningPrecision CNC Machining of Copper and Aluminum AllStainless SteelMachiningPrecision CNC Machining of Stainless Steel MateriaDie Steel MachiningPrecision CNC Machining of Die Steel MaterialsComposite Material MachiningPrecision CNC Machining of Composite Materials

Metal MachiningProtoypes and production partsTitanium Alloy MachiningPrecision CNC Machining of Titanium MaterialsCopper and Aluminum MachiningPrecision CNC Machining of Copper and Aluminum AllStainless SteelMachiningPrecision CNC Machining of Stainless Steel MateriaDie Steel MachiningPrecision CNC Machining of Die Steel MaterialsComposite Material MachiningPrecision CNC Machining of Composite Materials Plastic MachiningProtoypes and production parts

Plastic MachiningProtoypes and production parts